What Are the Common Fabric Testing Items and Test Instruments?

Fabric testing is fundamental in the textile industry to ensure the quality, performance, and durability of fabric for numerous applications. From assessing physical properties like tensile strength and abrasion resistance to evaluating colorfastness and dimensional balance, complete fabric testing helps producers meet industry requirements and purchaser expectations. Let’s discover the not unusual material testing items and instruments utilized in textile production:

Tensile Strength

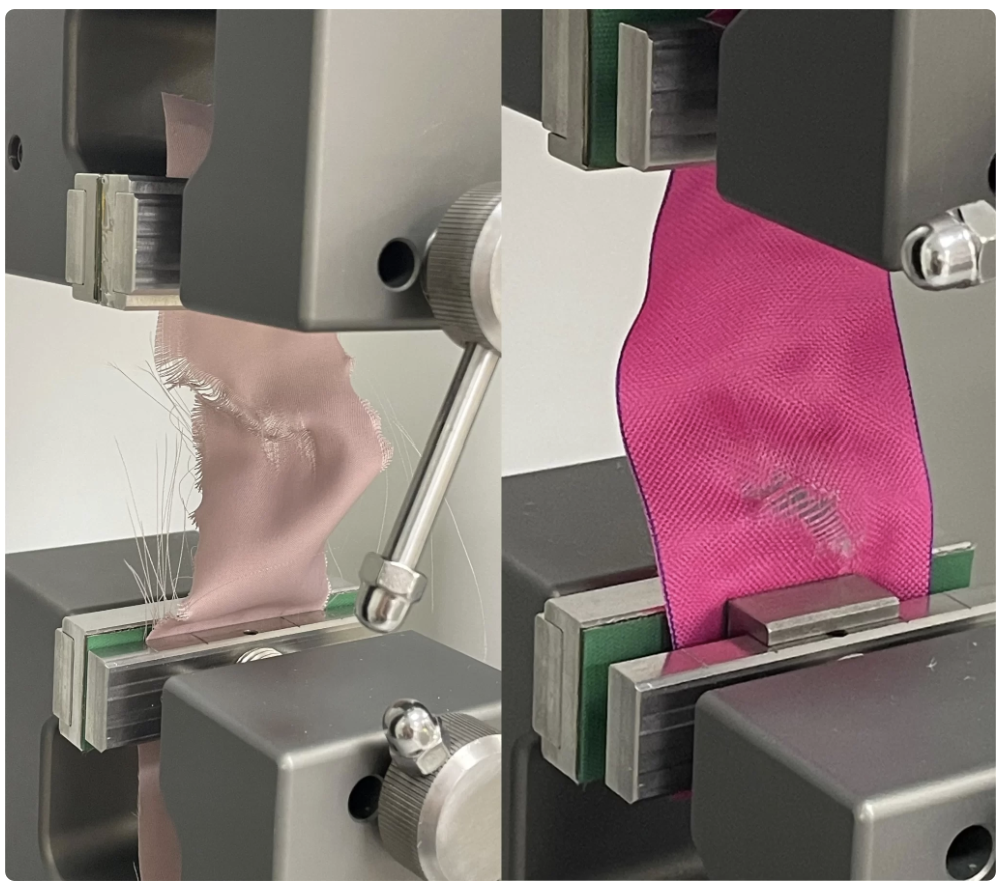

Tensile strength measures the maximum force a fabric can withstand earlier than breaking or tearing. It is critical for assessing fabric sturdiness and suitability for particular applications, including garb, home textiles, and technical textiles.

Tear Strength

Tear strength evaluates a fabric’s resistance to tearing or propagation of a tear. It is essential for assessing cloth performance in programs in which tear resistance is necessary, which includes shielding apparel and outside equipment.

Abrasion Resistance

Abrasion resistance measures a fabric’s capability to endure surface wear and damage on account of rubbing, friction, or repeated use. It is far particularly essential for fabrics used in upholstery, car interiors, and outdoor programs.

Colorfastness

Colorfastness refers to a fabric’s potential to retain its color while exposed to various external factors such as light, washing, and rubbing. Assessing colorfastness ensures that fabrics hold their look and shade intensity through the years.

Dimensional Stability

Dimensional balance evaluates a fabric’s ability to keep its authentic shape and length all through use and laundering. It is essential for preventing shrinkage, stretching, or distortion of fabric after washing or exposure to moisture.

Pilling Resistance

Pilling resistance measures a material’s resistance to the formation of drugs or small balls of fibers on its floor. It is fundamental for maintaining cloth appearance and texture through the years, in particular in garments and upholstery fabrics.

Water Repellency and Breathability

Water repellency assesses a material’s ability to withstand the penetration of water, at the same time as breathability measures its capability to allow moisture vapor to get away. These residences are imperative for outside and performance fabric utilized in rainwear, sportswear, and activewear.

Common Fabric Testing Instruments

Tensile Testing Machines practice managed anxiety to fabric samples to degree tensile power and elongation. These machines offer precious facts on fabric performance and durability, enabling producers to ensure product fantastic and consistency.

Tear Power testers measure the pressure required to rip a cloth specimen. These instruments evaluate material tear resistance and assist manufacturers assess cloth suitability for particular applications.

Martindale Abrasion Tester

Martindale abrasion testers simulate floor wear and abrasion by rubbing fabric specimens against a preferred abrasive floor. Those instruments quantify fabric abrasion resistance and assist manufacturers in determining product sturdiness and lifespan.

Colorfastness Tester

Colorfastness Testers examine fabric colorfastness to different factors such as mild, washing, and rubbing. These contraptions use standardized take a look at strategies to evaluate color retention and ensure fabric quality and appearance over time.

Dimensional Stability Tester

Dimensional stability tester gauges adjustments in fabric dimensions after washing or exposure to moisture. These devices help producers investigate material shrinkage, stretching, or distortion and make sure the product is good and consistent.

Pilling testers simulate cloth pilling by subjecting specimens to friction and abrasion. Those devices or instruments quantify fabric pilling resistance and help manufacturers expand fabric with an advanced look and durability.

Hydrostatic Head Tester and Moisture Vapor Transmission Rate (MVTR) Tester:

Hydrostatic head testers measure the resistance of a fabric to water penetration, whilst MVTR testers verify their breathability by gauging moisture vapor transmission rate. Those contraptions are integral for evaluating the overall performance of waterproof and breathable fabrics utilized in outside and overall performance clothing.

The fabric trying out is indispensable for ensuring the quality, overall performance, and sturdiness of textiles in the fabric industry. By completely trying out gadgets and instruments, producers can determine fabric properties as they should be and ensure compliance with industry requirements and consumer necessities. Of course, investing in superior testing technology and methodologies allows textile businesses to enhance products best, optimize production methods, and hold competitiveness in the international marketplace.