Shrinkage Test

Shrinkage test (dimensional or appearance change after washing) measures how much a fabric or garment changes size after being washed or exposed to heat. The test reveals the shrinkage rate – that’s the percentage amount it reduces in length and/or width. Knowing the shrinkage rate helps manufacturers and designers compensate so clothes keep fitting nicely after cleaning.

Which Fabric Has More Shrinkage?

Natural fabrics, like cotton, linen, and wool, shrink more. Synthetics, like nylon and polyester, shrink less. The list below breaks this down:

-

Cotton is infamous for excessive shrinking. This happens when it has not been pre-shrunk or exposed to hot water when drying. The shrinking rate of cotton can vary based on its quality and weaving. But, most cotton fabrics shrink 2-5%.

-

Linen comes from flax plants. It is likely to shrink a lot when first washed. As with cotton, linen fibers also constrict upon being exposed to water and heat. Linen can shrink a lot, up to 7% or 3-%. The amount depends on if it was pressed before use and how it was woven.

-

Wool:Wool is also a natural fiber that will shrink if it gets wet or washed. The amount of contraction depends on the type of wool, like merino wool and cashmere. It also depends on how it is processed. When washed in hot water or roughly handled, wool clothes can shrink by 3-5%.

-

Polyester:Polyester is a man-made fiber that does not shrink easily. It holds its shape well. It shrinks little even after high-temperature washing and drying. Usually, polyester fabrics have less than a 1 percent shrinking ratio.

-

Nylon is a synthetic material. It is known for its toughness and resistance to shrinkage. Like polyester, it is synthetic. Even when repeatedly washed, nylon fabric retains both shape and size. Rates of nylon are negligible compared to those of polyester.

What Is The ASTM Standard For Fabric Shrinkage Tests?

ASTM International (formerly the American Society for Testing and Materials) provides many standards. These instruments are used to test textiles for shrinkage. The standard deals with fabric shrinkage. It is ASTM D3774 – Standard Test Method for Width of Textile Fabric. According to this procedure, we can measure the width of fabrics before and after washing. This will show us if they shrank.

This standard enables measuring the width of cloth samples accurately. It does this to find the reduction in size from washing.

But, the fabric shrinkage test checks width changes. But, many other ASTM standards might also apply. They address different aspects of dimensional changes and performance. They are about testing shrinkages in textiles.

Take, for example, ASTM D4970. It is the Standard Test Method for Pilling Resistance and Other Related Surface Changes of Textile Fabrics. The test uses the Martindale Tester. The test checks how well fabric resists pilling after washing. ASTM D2203 is used to measure fabric stiffness. It tests bending, not shrinkage.

Also, the same scenario is considered when using these other related ASTM standards with ASTM D3774. It lets textile designers and researchers see into fabric contraction. It also shows its behavior after laundering. This approach includes everything. It helps create textiles that are very functional and durable. This lets them meet a wide range of demands in different sectors.

These ASTM standards are associated with ASTM D3774. They should be compared to it so that textile makers or researchers have complete knowledge. They must consider the impact on fabric performance and garment fit after washing. This approach allows for the development of textiles with better performance and longer life. It meets varied consumer needs across industries.

What Is The ISO Method Of Fabric Shrinkage Test?

The ISO shrinkage test is a standard way to test how materials respond to temperature. It focuses on changes in dimensions, like expansion or shrinking. This method was developed by the International Organization for Standardization (ISO). It is widely used in many sectors. It determines quality and tests materials like textiles, plastics, composites, and rubber.

The application of the ISO shrinkage test involves several crucial steps. First, the sample is prepared following certain standards. It involves cutting. The cutting may involve compressing or stretching. The type of cutting depends on the material and testing requirements. Thereafter, heating up or cooling down of samples using specific temperatures takes place.

It is crucial to treat things evenly. This ensures that results can be trusted. This is true throughout the heat-treatment process. Then, measurements are taken at different temperature intervals. They are taken with precise tools like gauges, microscopes, or optical instruments.

Measurements are followed by data analysis. This entails determining dimensional change relative to the initial dimension of samples. This computation is usually expressed in a percentage or another form of rate of change. This is obtained from mathematical formulas that are specified by the ISO standard.

Each ISO standard covers a specific shrinkage test method. The method is for a type of material and set of testing conditions. For instance, there are ISO 294-4 for plastics, ISO 175 for rubber, and ISO 3759 for textiles. Each gives procedures and parameters for its materials.

At the end of testing, we create a full results report. It details the test conditions, sample details, measurement data, and calculations. It also includes any other needed observation. These help us understand the material’s properties. They also help us control product quality and improve manufacturing.

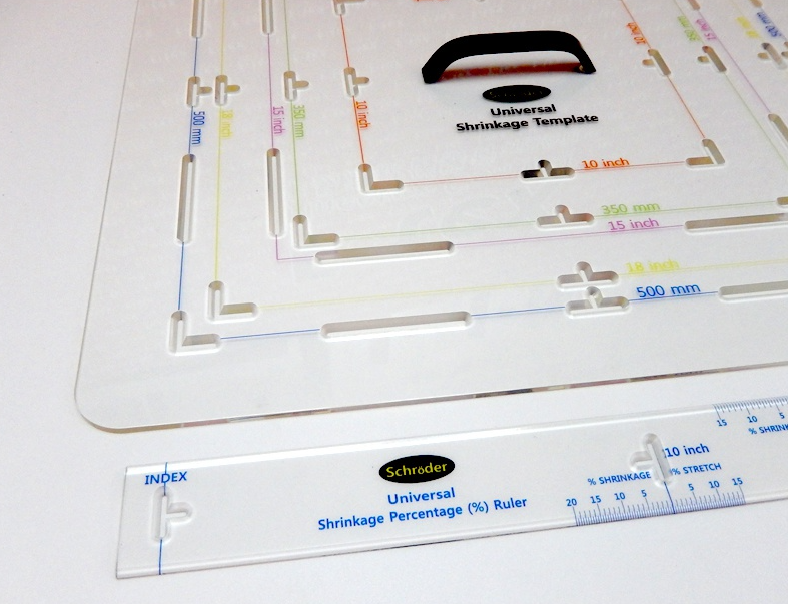

How To Calculate The Shrinkage Percentage Of Fabric?

To calculate fabric shrinkage, compare dimensions before washing or drying with after washing or drying. Here’s how:

-

Measure Fabric Before Laundering:

Measure fabric dimensions before washing. Use a ruler or any measuring tool, such as a tape measure. For example, if you are doing length by width on one piece of cloth, record that in inches or centimeters.

-

Launder Fabric:

Obey the instructions for cleaning the fabric. It means washing and drying the material at set temperatures and cycle types. Ensure that you recreate, to the best of your ability, how it will be laundered when in use.

-

Measure Fabric After Laundering:

After laundering and drying, measure the fabrics again. Use the same gadgets as before to get their dimensions. Document these measurements.

-

Calculate Shrinkage:

The following formula can be used to calculate shrinkage percentage:

Shrinkage Percentage = ((Original Dimension – Final Dimension) / Original Dimension) x 100

-

Subtract the final dimension (after laundering) from the original dimension (before laundering).

-

Divide the result by the original dimension.

-

Multiply the quotient by 100 to express the result as a percentage.

For example, if the fabric was 100 inches long initially and 95 inches long after washing, it would be

((100 – 95) / 100) x 100 = (5 / 100) x100 = 5%

-

Interpretation:

The percentage of shrinkage calculated represents the amount of fabric contraction after laundry. Positive values show the garment shrank. Negative ones suggest it grew or stretched.

-

Repeat as Necessary:

You might want to use several fabric samples. Average the amounts of shrinkage found. This will make the results more accurate.

From these steps and math, you can find what part of the substance was removed in washing. These findings are very useful for making decisions on textile and apparel production. They are also useful in other areas where fabric performance matters most.

Sign up for advice

- Hotline0902 596 388

- emailsale1@amitec.com.vn