Durability test

Pilling Resistance

Fabric pilling resistance are two key indicators of textile durability during use and wear. Pilling refers to the formation of small balls of entangled fibers on the fabric surface, while abrasion leads to loss of fibers or mass. Testing these properties is...

Accelerated ageing test

Accelerated ageing test is a method used to estimate the long-term durability and performance of materials or products by exposing them to elevated stress conditions, such as increased temperature, humidity, light, or mechanical stress, over a shorter period. This test...

Bursting Strength

This test method describes the measurement of the resistance of textile fabrics to bursting. The force required to rupture a fabric by distending it with a force applied at right angles to the plane of the fabric under specified conditions....

Tear strength

Testing Principle The principle of tearing strength is fabric tearing, also known as tearing, fabric local yarns are subjected to a concentrated load, so that the phenomenon of fabric tearing. Fabrics in the process of use, clothing hooked by the object,...

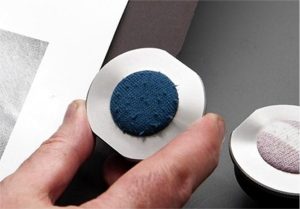

Martindale Testing in Textile

Martindale testing is used to evaluate a fabric’s resistance to two main types of wear and tear – abrasion and pilling. Abrasion: Imagine your favorite pair of jeans rubbing against a chair repeatedly. Over time, you might notice the fabric...

Tensile strength

Tensile testing is one of the most widely used physical tests for textiles and other materials. By measuring the force required to elongate a specimen to breaking point, the textile properties can be determined that will allow designers and quality...