Drying rate

Importance of Moisture Wicking and Drying Rate

Sweat pouring down your face. Heart pounding. Legs burning as you push to sprint the last mile. But suddenly you feel a chill creep over your soaked shirt and shorts. Within minutes, you’re shivering instead of charging ahead to crush your new PR.

We’ve all experienced that bone-chilling sensation when drenched workout wear betrays us. The damp cotton plastered against our skin eventually turns our sweat against us!

But what if a special kind of fabric could whisk away sweat, keeping it from ever accumulating next to your body in the first place?

And what if those fabrics then dried in mere minutes rather than heavy, clinging hours?

These are what we call Moisture-wicking and Quick-dry fabrics.

With the right high-tech moisture-wicking and quick-dry activewear, you won’t suffer the consequences of sweat-drenched clothing again.

These fabrics offer a breathable, comfortable barrier between your hard-driving intensity and the havoc all that perspiration can wreak.

So, if you’re intrigued by what modern fabric engineering can do?

Or curious about exactly how moisture-wicking works its magic?

Then, you’ve come to the right place!

In this complete guide, we’ll give you an insider’s look into cutting-edge moisture-wicking and quick-dry fabrics for athletic apparel.

Let’s get started!

What is Moisture Wicking Fabric?

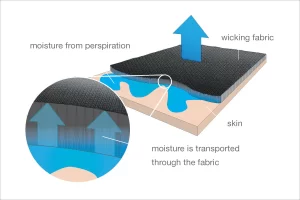

First question: What exactly makes a moisture-wicking fabric? Simply put, these fabrics move sweat and moisture away from your skin to the fabric’s outer face. The moisture then evaporates instead of absorbing into the material. This keeps you drier compared to fabrics like cotton that soak up perspiration.

Moisture-wicking ability relies on a physical process called capillary action. Have you ever noticed how water seems to defy gravity as it climbs up a paper towel? That’s capillary action at work. It allows liquids to flow through the tiny spaces in certain materials.

In moisture-wicking fabric, the spaces between the fabric’s fibers form miniature channels. As sweat meets the fabric, it gets drawn into these channels and propelled outward. So rather than just getting absorbed right at the skin’s surface, the moisture gets transported away.

Now…

What Is Quick Dry Fabric?

Similarly, a quick dry fabric is engineered to do exactly what the name promises—dry rapidly. Of course, moisture wicking helps speed up drying already. But quick-dry fabrics take things even further through fabric construction and special coatings.

Quick dry fabrics usually have a loose-knit or breathable weave. This allows fresh air to pass through easily and evaporate moisture. Many also have durable water-repellant (DWR) finishes or other coatings. These treatments cause water to bead up and roll right off the fabric.

Between moisture-wicking, breathable construction, and water-repelling finishes, quick dry fabric dries 50% faster than even cotton. For high-energy activities, that means you stay comfortable even when you work up a major sweat. No one wants clammy, wet clothes plastered to them for the rest of a bike ride or run!

How to Achieve Moisture Wicking and Quick Drying Fabrics

When researching athletic apparel, you’ll probably encounter mentions of moisture-wicking and quick-dry fabric technologies. But have you ever wondered how fabrics gain these useful performance properties? Achieving effective moisture wicking relies on two key factors:

First, a strong capillary action to pull moisture along the fabric’s fibers.

And second, a construction that enables rapid evaporation of that moisture outward.

There are a few main methods manufacturers use to build fabrics with these traits:

Specialized chemical finishes are very common. Applying hydrophobic treatments makes a fabric resist absorbing sweat while hydrophilic finishes help draw moisture outward. These can be applied to just one face of fabric or different finishes on either side to enhance the pull of moisture in one direction.

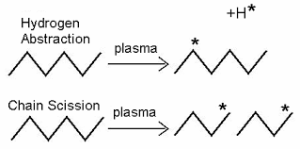

Plasma treatments are another technique. This exposes the fabric to plasma gases under very precise conditions to alter fiber surfaces. It can make them either attract or resist moisture. The effects gradually fade over time though.

Finally, structural fabric design itself plays a role too. Using different weaves or knits, weights, and fiber blends controls absorption and airflow. For example, a double-layer mesh fabric with larger holes facing the body but tighter mesh outside optimizes outward moisture movement and evaporation.

Synthetic and wool blends excel at moisture-wicking thanks to smooth fiber shapes that resist absorbing liquids. But specific processing enhancements take things even further. For instance, creating ridges, grooves, curves, or chambers in fabric surfaces gives moisture channels to follow outward.

In the best athletic fabrics, structural design works together with specialized chemical finishes and plasma treatments. This multi-step approach ensures effective moisture-wicking sweat after sweat, wash after wash.

Sign up for advice

- Hotline0902 596 388

- emailsale1@amitec.com.vn