Martindale Abrasion Pilling Tester

1. What is a Martindale Abrasion Pilling Tester?

The Martindale Abrasion and Pilling Tester, often referred to simply as the Martindale Tester, is a workhorse in the textile industry. This apparatus serves a critical purpose: evaluating a fabric’s resistance to two main types of wear and tear – abrasion and pilling.

Understanding Abrasion and Pilling

Abrasion:

Imagine your favorite pair of jeans rubbing against a chair repeatedly. Over time, you might notice the fabric thinning or even developing holes in those high-friction areas. This gradual wearing away of a fabric’s surface due to rubbing against other materials is precisely what abrasion is. It can significantly impact the lifespan and aesthetics of a textile product.

Pilling:

Have you ever noticed those pesky little balls of fiber forming on the surface of your sweater? That’s pilling, and it occurs when loose fibers on the fabric surface tangle and clump together. While not necessarily a functional issue, pilling detracts from the overall appearance and quality of the textile.

How The Martindale Tester Saves the Day?

The Martindale Tester simulates these wear and tear mechanisms in a controlled laboratory setting. Here’s a closer look at how it functions:

Sample Preparation:

The testing process begins with preparing a sample of the fabric under evaluation. Following specific standards, a circular piece is typically cut from the material.

Test Configuration:

This prepared sample is then mounted on a rotating arm within the tester. The opposing rubbing surface can vary depending on the test type. For abrasion testing, a standard abrasive material might be used. For pilling evaluation, another fabric sample, often a standard woolen fabric or even the same fabric itself, may be used as the rubbing surface.

The All-Important Rubbing Motion:

The Martindale Abrasion and Pilling Tester is programmed to run for a set number of cycles, replicating the expected duration of wear the fabric might encounter in its intended application. During each cycle, the rotating arm rubs the fabric sample against the opposing surface in a complex path known as a Lissajous pattern. This intricate path ensures all areas of the sample experience rubbing at various angles, mimicking real-world wear scenarios where the fabric doesn’t rub in just one direction.

Evaluation – The Final Verdict: Once the test is complete, the fabric sample undergoes a thorough visual inspection. For abrasion testing, this inspection focuses on identifying signs of wear. In the case of pilling evaluation, the degree of pilling formation is assessed.

2. What is a Martindale Abrasion Tester Diagram?

While a detailed technical diagram of the Martindale Abrasion and Pilling Tester can be intricate, understanding the basic concept behind its internal workings is quite interesting. Imagine the diagram as a blueprint for a machine with multiple testing stations, each designed to mimic real-world wear and tear on a fabric sample. Here’s a breakdown of the key components you might see in a simplified version of the diagram:

-

Testing Station:

Each station typically features a circular base that holds the fabric sample in place.

-

Sample Holder:

Think of this as a small clamp or clip that securely attaches the circular fabric sample to the base. It ensures the fabric stays taut and experiences consistent rubbing throughout the test.

-

Rotating Arm:

Picture a short arm extending upwards from the base. This arm holds the sample holder and rotates, mimicking the rubbing motion the fabric might experience in real-life use.

-

Weight:

A designated weight is placed on top of the rotating arm, pressing down on the fabric sample. This weight simulates the pressure the fabric encounters during use. Heavier weights might be used for upholstery fabrics, while lighter weights might be used for delicate materials.

-

Opposing Rubbing Surface:

Depending on the test type, this surface can vary. For abrasion testing, imagine a rough, textured plate representing surfaces the fabric might rub against, like furniture or backpacks. In pilling evaluation, this surface could be another fabric sample, often a standard woolen fabric, mimicking the rubbing of fabric fibers against each other.

-

Drive Mechanism:

This unseen component is responsible for rotating the arm that holds the fabric sample and the weight. It ensures consistent speed throughout the test.

-

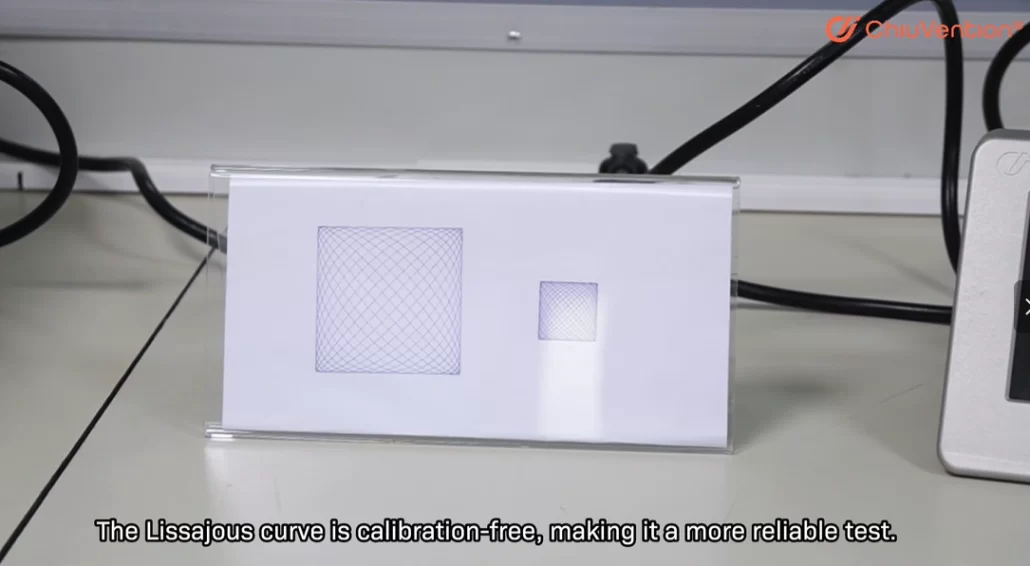

Lissajous Path:

This might sound complex, but imagine the path of the rotating arm as an oval shape, not a simple back-and-forth motion. This oval path ensures all areas of the fabric experience rubbing at various angles. Think of it like a fabric rubbing against different surfaces at different angles during everyday use.

Remember, this is a simplified explanation. Actual Martindale Testers might have additional components or variations in design depending on the manufacturer. However, the core principle remains the same.

3. What is the Martindale Abrasion Tester Working Principle?

The Martindale Abrasion and Pilling Tester may seem like a simple machine, but its working principle involves a well-defined process to accurately assess fabric durability. Here’s a breakdown of the key steps involved:

- Sample Preparation: Setting the Stage:

The testing journey begins with preparing the fabric sample. Following specific standards, a circular piece, typically around 38 or 140 millimeters in diameter, is cut from the material under evaluation. This ensures consistency and allows for comparison between different fabrics tested using the same method.

- Test Configuration: Putting the Pieces Together:

Once the sample is prepared, it’s time to configure the Martindale Tester for the specific test type – abrasion or pilling. Here’s what happens:

Sample Mounting:

The prepared fabric sample is securely fastened onto the sample holder on the rotating arm of the testing station.

Opposing Rubbing Surface Selection:

Depending on the test type, the appropriate opposing rubbing surface is chosen and positioned. For abrasion testing, a standard abrasive material with a defined texture is used. For pilling evaluation, the opposing surface could be another fabric sample, often a standard woolen fabric or even the same fabric itself.

Weight Application:

A predetermined weight is applied to the top of the rotating arm, pressing down on the fabric sample. This weight simulates the pressure the fabric might experience during its actual use. The specific weight used depends on the test standard and the type of fabric being evaluated.

- The Crucial Rubbing Motion: Replicating Real-World Wear:

With everything set up, it’s time for the core functionality of the Martindale Tester – the rubbing motion. Here’s how it works:

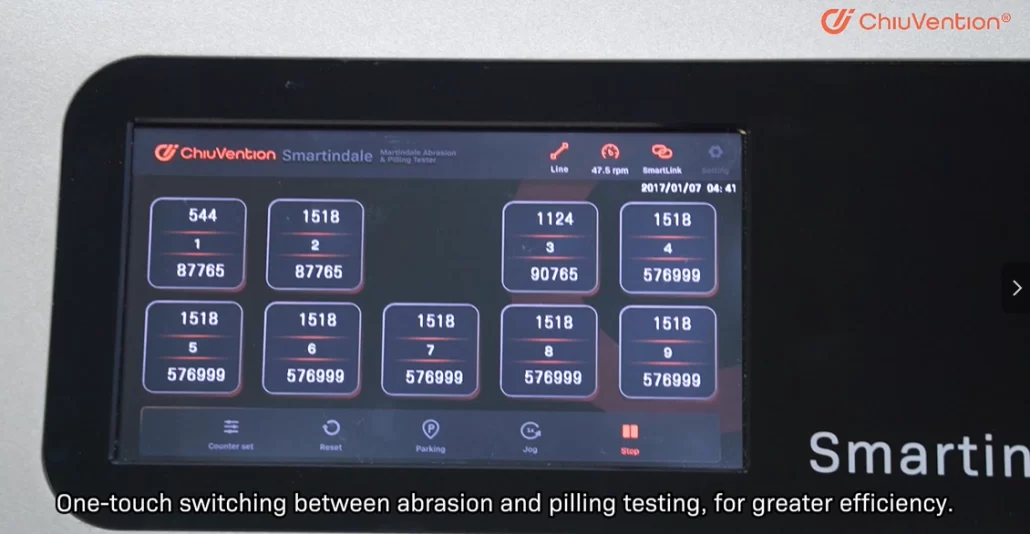

Programmed Cycles:

The tester is programmed to run for a specific number of cycles, replicating the expected wear duration for the fabric in its intended application. For instance, upholstery fabrics might need to endure more rubbing cycles compared to delicate scarves.

The Lissajous Path:

Unlike a simple back-and-forth motion, the rotating arm holding the fabric sample follows a complex path known as a Lissajous pattern. This intricate oval-shaped path ensures all areas of the fabric experience rubbing at various angles. Imagine a fabric rubbing against different surfaces throughout the day, not just in one direction. The Lissajous pattern replicates this real-world scenario for a more accurate evaluation.

Consistent Speed:

The drive mechanism of the tester ensures the rotating arm maintains a consistent speed throughout the programmed cycles. This controlled speed allows for standardized testing and reliable comparisons between different fabrics.

- Unveiling the Results: The Fabric’s Story:

After the pre-determined number of cycles is complete, the fabric sample is removed from the tester and undergoes a thorough visual inspection. Here’s what the inspection reveals:

Abrasion Testing:

For abrasion testing, the fabric sample is examined for signs of wear and tear. This might include thinning, fraying, or even the formation of holes. The number of cycles endured before reaching a pre-defined level of wear determines the fabric’s abrasion resistance.

Pilling Evaluation:

In pilling evaluation, the focus is on assessing the degree of pilling formation on the fabric surface. Standardized grading systems, often using a five-point scale, are used to quantify the severity of pilling observed. Higher grades indicate less pilling and superior resistance.

By analyzing the results of the visual inspection and the number of cycles endured before reaching a set level of wear or pilling, the Martindale Tester provides valuable data on the fabric’s durability.

Sign up for advice

- Hotline0902 596 388

- emailsale1@amitec.com.vn