Elmendorf Tear Test

1. What Is The Elmendorf Tear Test?

The Elmendorf Tear Test is a standardized method specifically designed to evaluate a fabric’s resistance to tearing. Tearing refers to the progressive ripping or snagging of fabric fibers, often initiated by a sharp object or concentrated force. This property significantly impacts a fabric’s functionality and durability across various applications.

Imagine a piece of clothing, like denim jeans, that easily rips at the seams due to everyday wear. Or consider upholstery fabric that tears prematurely when brushed against. The Elmendorf Tear Test helps prevent such scenarios by providing a quantitative measure of a fabric’s tear strength.

The test operates on a straightforward principle. A specially designed instrument called the Elmendorf Tear Tester utilizes a pendulum mechanism. A precisely cut fabric sample with a pre-made notch is secured in the tester. The pendulum, with a controlled weight, is raised to a specific height, storing potential energy. Upon release, the pendulum swings down, impacting the fabric specimen at the pre-cut notch.

As the pendulum continues its upward swing, it exerts a force to further tear the fabric. This force required to propagate the tear is precisely measured and recorded. Higher force values indicate greater tear strength, signifying the fabric’s ability to resist ripping or snagging. The measured tear strength value, typically expressed in grams (g) or Newtons (N), serves as a benchmark for assessing the fabric’s suitability for its intended use.

2. What Is The Test Principle Of The Elmendorf Tear Test?

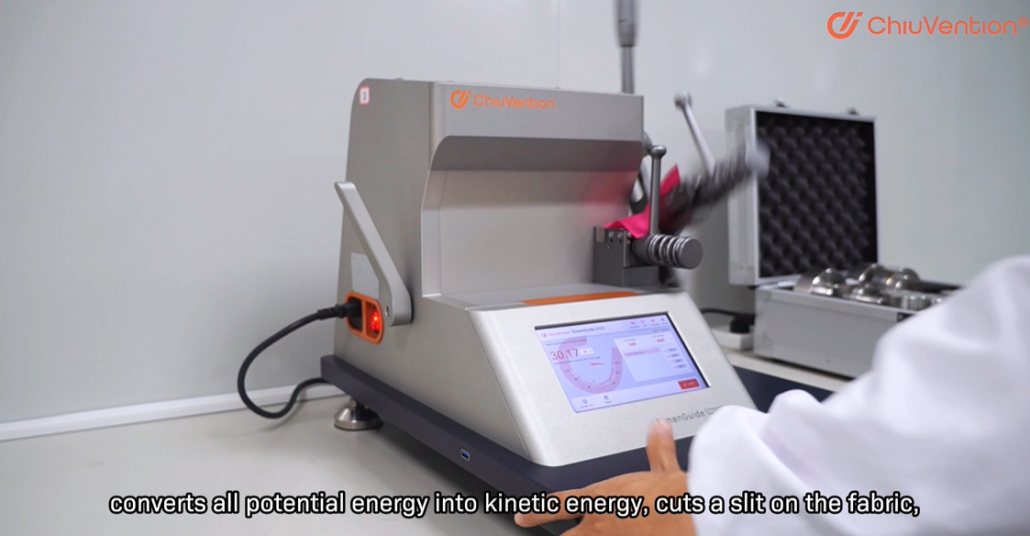

The Elmendorf Tear Test relies on a fundamental scientific principle: the conversion of energy. The test leverages the concept of potential energy stored in a raised object, which is then converted into kinetic energy during movement and ultimately used to perform work, in this case, tearing the fabric.

Here’s a closer look at the science behind the Elmendorf Tear Test:

Potential Energy:

The Elmendorf Tester features a pendulum, a weighted arm free to swing around a fixed pivot point. When raised to a specific height, the pendulum stores potential energy due to its position and the force of gravity acting upon it.

Conversion to Kinetic Energy:

As the pendulum is released, it begins to swing downward. During this descent, the potential energy gradually converts into kinetic energy, the energy of motion. The pendulum gains speed as it approaches the fabric sample.

Force Application and Tear Propagation:

Upon reaching the bottom of its swing, the pendulum impacts the pre-cut notch in the fabric specimen. This impact applies a concentrated force to the fabric at the weakest point, the notch.

Work Done: Tearing the Fabric:

The force exerted by the pendulum initiates a tear in the fabric. However, the tear doesn’t stop there. As the pendulum continues its upward swing, it pulls against the fabric, further propagating the tear.

Measuring the Resistance:

Here’s where the key measurement occurs. Throughout the tearing process, the Elmendorf Tester precisely measures the force required by the pendulum to keep ripping the fabric. This measured force value represents the fabric’s resistance to tearing.

The higher the force required to propagate the tear, the greater the tear strength of the fabric. This value serves as a crucial data point for evaluating a fabric’s suitability for various applications.

3. Which Fabrics Should Be Tested For Tear Resistance Testing?

Tear resistance testing plays a vital role in ensuring the functionality and longevity of various fabrics across diverse applications. Here’s a breakdown of some key fabric categories that benefit from Elmendorf Tear Testing:

A) Fabrics for Everyday Wear and Tear:

Apparel Fabrics:

Fabrics used in clothing, particularly those subjected to frequent wear and tear, benefit from tear resistance testing. This includes denim for jeans, canvas for bags and backpacks, and leather for jackets and shoes. Understanding the tear strength helps ensure these garments can withstand everyday use without ripping easily.

Upholstery Fabrics:

Upholstery fabrics used in furniture need to be resistant to snags and tears. Testing helps assess their ability to handle regular use, occasional snags from pets or sharp objects, and ensure they maintain their appearance over time.

B) Fabrics for Performance and Safety:

Technical Textiles:

Fabrics used in specialized applications, often requiring high strength and tear resistance, benefit from testing. This includes parachute materials, airbags in vehicles, and tents for outdoor use. Ensuring these fabrics possess adequate tear strength is crucial for safety and functionality.

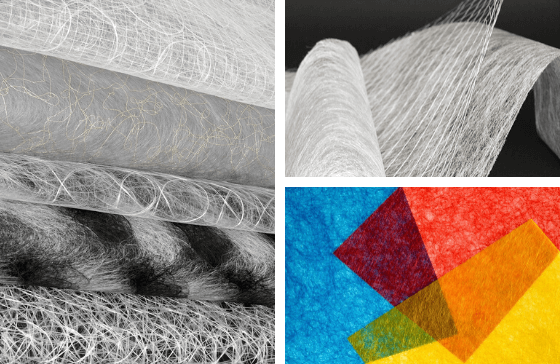

Nonwoven Fabrics:

These fabrics, formed by bonding fibers without weaving or knitting, are used in various applications. Testing tear strength helps assess their suitability for disposable wipes, filters, and insulation materials, where maintaining structural integrity is important.

C) Fabrics for Medical Applications:

Medical Textiles:

Fabrics used in medical settings, such as surgical gowns and drapes, require specific tear-resistance properties. Testing ensures they can withstand handling during procedures while maintaining a barrier function.

By incorporating Elmendorf Tear Testing into quality control procedures, manufacturers can ensure their fabrics meet the demands of their intended use. This not only enhances product performance and durability but also contributes to user safety and satisfaction.

4. Which Kind Of Material Has The Higher Tear Strength?

When it comes to tear resistance, understanding which materials generally perform better can be a valuable asset. However, it’s important to remember that tear strength is a complex property influenced by several factors. Here, we’ll explore some key material characteristics that tend to contribute to higher tear strength in fabrics.

A. Fiber Properties:

In general, synthetic fibers like nylon, polyester, and aramid fibers (e.g., Kevlar) often exhibit higher tear strength compared to natural fibers like cotton or silk. This is because synthetic fibers tend to be stronger and more resilient.

The inherent strength of the individual fibers plays a crucial role. Fibers with higher tenacity, meaning they can withstand greater forces before breaking, contribute to a fabric’s overall tear resistance.

B. Fabric Construction:

Weave Type: Woven fabrics generally demonstrate greater tear strength compared to knitted fabrics. This is due to the interlacing of yarns in woven fabrics, creating a more robust structure that resists tearing forces better. The specific weave pattern (e.g., plain weave, twill weave) can also influence tear strength.

Yarn Count and Twist: Fabrics made with a higher yarn count, meaning a thicker yarn, tend to have greater tear resistance compared to those with a lower yarn count. Similarly, yarns with a higher twist, where the fibers are more tightly intertwined, can contribute to improved tear strength.

C. Finishing Treatments:

Certain finishing treatments, such as applying resin coatings, can enhance a fabric’s tear resistance. These coatings act as a protective layer, offering additional reinforcement and reducing the ease of tearing.

5. What Is The Tear Test Procedure?

Understanding the process behind the Elmendorf Tear Test is essential for appreciating the method’s accuracy and reliability. So let’s understand the procedure:

A. Sample Preparation:

The testing process begins with meticulous sample preparation. Fabric specimens are cut according to specific standards, typically rectangular with a precise central notch. The notch size and orientation are crucial, as they influence the tear initiation point and subsequent tear path. International standards like ASTM D1424 define the exact dimensions and cutting procedures for sample preparation.

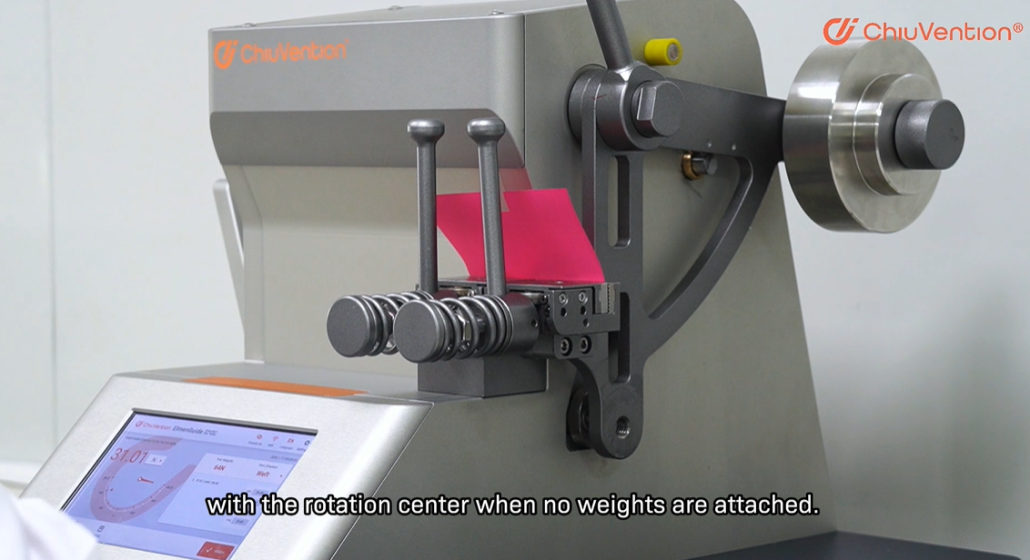

B. Specimen Clamping:

Once prepared, the fabric sample is securely clamped in the Elmendorf tester. The clamping mechanism holds the specimen firmly in place, ensuring a consistent starting point for the tear propagation. Proper clamping ensures the applied force acts solely on tearing the fabric, eliminating any influence from slippage or movement within the clamps.

C. Pendulum Setup and Release:

The Elmendorf tester features a pendulum, a weighted arm free to swing around a fixed pivot point. The pendulum weight is precisely defined by the testing standard. The pendulum is then raised to a specific height, converting its position into potential energy. This standardized height ensures consistent testing conditions and allows for repeatable measurements. Once at the designated height, the pendulum is released, initiating the tear test.

D. Tear Initiation and Propagation:

As the pendulum swings downward, it impacts the pre-cut notch in the fabric specimen. This impact initiates a tear in the fabric at the weakest point, the notch. However, the tear doesn’t stop there. The momentum of the pendulum carries it upwards, and during this upward swing, the pendulum exerts a force on the fabric. This force acts to further propagate the tear along the length of the specimen.

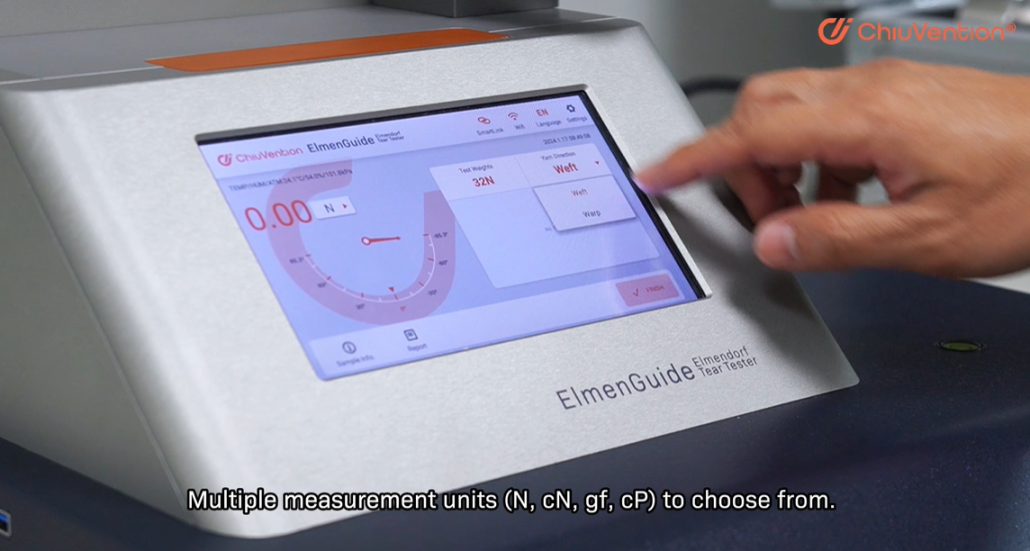

E. Force Measurement and Recording:

Throughout the tearing process, the Elmendorf tester precisely measures the force required by the pendulum to keep ripping the fabric. This measured force value represents the fabric’s resistance to tearing. The tester is equipped with sophisticated sensors and a data acquisition system that captures this force value electronically.

F. Result Interpretation:

Once the tear reaches a predetermined length or the pendulum loses its momentum, the test is complete. The recorded force value, typically expressed in grams (g) or Newtons (N), serves as the raw data point for interpreting the fabric’s tear strength. This value is then compared to industry standards or pre-determined specifications for the intended use of the fabric.

6. What Is The Elmendorf Tear Test Standard ASTM D1424?

In the world of standardized testing, consistency is paramount. For the Elmendorf Tear Test, ASTM D1424 stands as the most widely recognized international standard. This designation by the American Society for Testing and Materials (ASTM) ensures a globally accepted method for measuring fabric tear strength.

ASTM D1424 meticulously outlines the test method and test procedure, guaranteeing that Elmendorf Tear Tests conducted in different laboratories around the world follow the same principles. This standardization allows for reliable comparison of tear strength values across various fabrics and applications.

Now that we have established the significance of ASTM D1424 in standardizing the Elmendorf Tear Test, let’s delve deeper and explore the specific steps involved in the testing procedure. This breakdown will provide a clear understanding of how the test is conducted to measure a fabric’s tear strength.

- Sample Preparation:

The testing process begins with meticulous attention to detail. Fabric specimens are precisely cut according to the dimensions outlined in ASTM D1424. These specimens are typically rectangular and feature a central notch with defined measurements.

2. Specimen Clamping:

Once prepared, the fabric specimen is securely fastened within the Elmendorf tester’s clamps. This clamping mechanism ensures a consistent starting point for the tear.

3. Pendulum Setup and Release:

The Elmendorf tester features a pendulum, a weighted arm free to swing around a fixed pivot point. The weight of the pendulum is clearly defined by ASTM D1424. This pendulum is then raised to a specific height, converting its position into potential energy.

4. Tear Initiation and Propagation:

As the pendulum swings downward, it impacts the pre-cut notch in the fabric specimen. This impact initiates a tear in the fabric at its weakest point, the notch. However, the tear doesn’t stop there. The momentum of the pendulum carries it upwards, and during this upward swing, the pendulum exerts a force on the fabric.

5. Force Measurement and Recording:

Throughout the tearing process, the Elmendorf tester precisely measures the force required by the pendulum to keep ripping the fabric. This measured force value represents the fabric’s resistance to tearing. The tester is equipped with sophisticated sensors and a data acquisition system that electronically captures this force value.

Sign up for advice

- Hotline0902 596 388

- emailsale1@amitec.com.vn