Bursting Strength Test

What Are The Different Types Of Bursting Strength Test?

Several methods assess fabric burst strength for specific applications and materials. These tests ensure material durability and aid quality control in fabric production. Manufacturers rely on this test to ensure their products meet high-performance standards. This leads to improved durability, customer satisfaction, and reduced product failures.

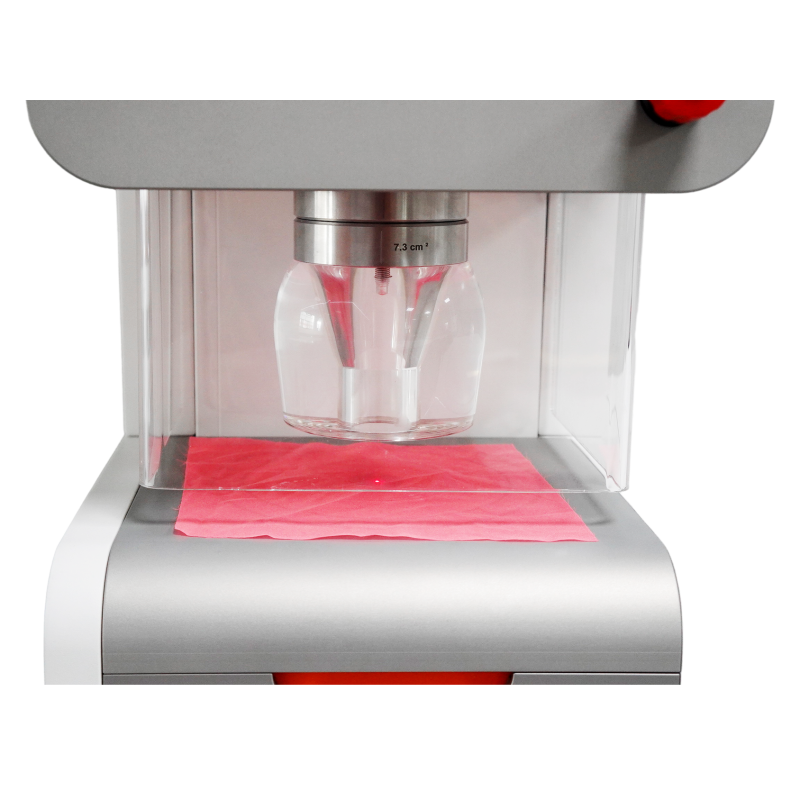

Hydraulic Diaphragm Test

One method is the hydraulic diaphragm test. This test involves placing a fabric sample over a rubber diaphragm. The diaphragm is then expanded by hydraulic fluid until the fabric bursts. This test measures the bursting pressure, which indicates the fabric’s stress resistance.

It mimics real-world pressure conditions that fabrics might encounter during use. This includes pressures from weight, movement, and environmental factors. The test provides a realistic measure of how well a fabric can withstand stress.

This method is particularly useful for industrial and heavy-duty textiles. These materials often face extreme conditions. So, they need to maintain their integrity under high stress. Examples include fabrics used in construction, outdoor gear, and protective clothing. The hydraulic diaphragm test ensures these textiles can perform well over time.

The procedure is straightforward yet very effective. The fabric is often clamped over the diaphragm to prevent slipping. Hydraulic fluid is then pumped into the diaphragm, causing it to expand. As the pressure increases, the fabric stretches until it reaches its bursting point. The exact pressure is then recorded as the fabric’s bursting strength.

Key benefits of the hydraulic diaphragm test include:

- Provides precise measurements of fabric strength.

- Simulates actual conditions that textiles will face in use.

- Suitable for a variety of heavy-duty and industrial fabrics.

- Consistent results help in maintaining quality control in production.

Pneumatic Test

Another technique for assessing fabric strength is the pneumatic test. This method utilizes air pressure to stretch the fabric until it ruptures. The pneumatic test relies on compressed air. This makes it particularly well-suited for lightweight fabrics or those with significant elasticity.

During the pneumatic test, a fabric sample is well clamped over an aperture. Compressed air is then introduced beneath the fabric. As the air pressure increases, the fabric stretches until it bursts. The specific pressure at which the fabric ruptures is then recorded. This provides a measure of its tensile strength.

The pneumatic test is ideal for delicate or stretchy materials. Fabrics used in apparel and sportswear need this type of testing. These materials need to withstand various stresses while maintaining flexibility and comfort. The pneumatic test offers reliable data on fabric elasticity. It ensures that garments made from these materials will be durable and comfortable.

Key benefits of the pneumatic test include:

- Air pressure provides a gentler means of testing. It reduces the risk of damaging delicate fabrics.

- Offers accurate measurements of tensile strength and elasticity.

- It is often tailored for lightweight and elastic materials used in clothing.

- It can be often adapted for various fabric types and sizes.

The procedure for conducting a pneumatic test involves several steps. First, the fabric is positioned and clamped to prevent movement. Compressed air is then released under the fabric, causing it to expand. The process continues until the fabric reaches its rupture point. The pressure reading at this moment represents the fabric’s tensile strength.

Ball Burst Test

Ball burst tests are often used in furniture and automotive textiles. A steel ball presses against the fabric until it bursts. This test shows fabric performance under concentrated force.

Procedure of Ball Burst Test

The fabric is first clamped before testing. A steel ball is then positioned above the fabric. Pressure is then applied, driving the ball into the fabric. The pressure increases until the fabric bursts. The force at bursting is finally recorded for analysis.

Applications of Ball Burst Test

This test simulates everyday wear and tear in upholstery. It mirrors the stress fabrics endure in vehicle seats. High-stress environments like these require durable materials. Essential for quality assurance in these demanding applications.

Benefits of Ball Burst Test

- Provides precise measurements of fabric strength.

- Mimics real-world conditions faced by upholstery and automotive textiles.

- Suitable for various types of fabrics.

- Consistent results enhance production quality control.

Sign up for advice

- Hotline0902 596 388

- emailsale1@amitec.com.vn