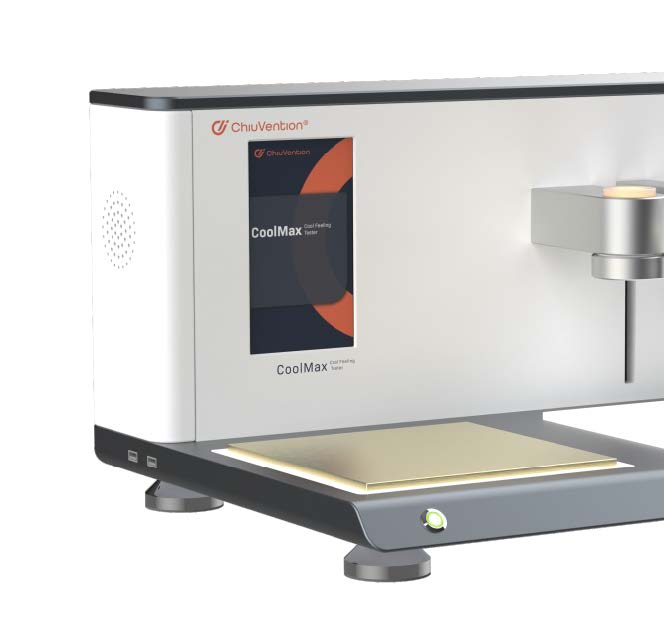

CoolMax Cool Feeling Tester

Testing textiles with instant cooling

CoolMax Cool Feeling Tester assesses cooling effect of textiles. The test applies to knitted and woven fabrics. CoolMax can simulate real-life usage scenarios. High-precision temperature sensors will record instantaneous temperature changes. The software will analyze the data and generate Q-max values. The test takes seconds. It has adjustable parameters and yields very reliable results.

CoolMax is connected via IoT to the SmarTexLab APP in the phone/PC. And The app can connect to ERP/LIMS via an API. Or, the instrument can connect directly to ERP/LIMS. There are test orders and sample information in the system, and the instrument can start the test and record the sample info, test process, and results. The system will then summarize these into a test report. The report can be sent to SmarTexLab or ERP/LIMS. The relevant parties can view the report in real time.

Lab operator can monitor tests for many instruments at once. They can also change test requirements, get alerts before tests end, and stop or repeat tests remotely. In SmarTexLab, you can set up programs to start or stop the instruments. You can chat with ChiuVention service staff for quick support. You’ll get reminders that instruments need calibration, maintenance, and new consumables. Regular OTA remote upgrades are available.

Feature & Advantage

Fast and Flexible

CoolMax takes 10 seconds to test. It’s ideal for batch testing in textile R&D, production, and quality control. Adjustable parameters: Test parameters (e.g., heating plate temperature, contact pressure) can be set to different standards.

More reliable test results.

CoolMax simulate real-use scenarios. The heating plate is heated to the average human body temperature (35 ℃±0.5℃). It makes full contact with the fabric’s surface. A high-precision temperature sensor records the instant temperature change. The software analyzes this and generates the Q-max value.

Sign up for advice

- Hotline0902 596 388

- emailsale1@amitec.com.vn