Demand Trends in the Textile and Garment Industry

- Quality Assurance and Brand Reputation: As consumers demand higher quality and longer-lasting garments, especially for active, outdoor, and technical wear, the need for rigorous testing like jungle and hydrolysis tests has increased. Brands want to ensure their products meet these expectations and maintain their reputation for durability.

- Global Market Expansion: With garments being sold in a variety of climates around the world, manufacturers need to ensure that their products perform well under different environmental conditions, driving the demand for such tests.

- Sustainability Concerns: As the industry moves towards more sustainable practices, ensuring the longevity of garments is a priority. Testing for durability under challenging conditions supports this goal by reducing the need for frequent replacements, thereby minimizing waste.

The demand to ensure product durability, particularly for garments exposed to harsh environmental conditions, especially relevant for outdoor, activewear, and technical textiles, where performance and longevity are critical to brand success. Accelerated ageing test (jungle or hydrolysis test) in the textile and garment industry are increasing recently and driven by this need. This test simulates the effects of aging over time, allowing manufacturers to predict the lifespan and potential failure modes of their products without waiting for real-time aging.

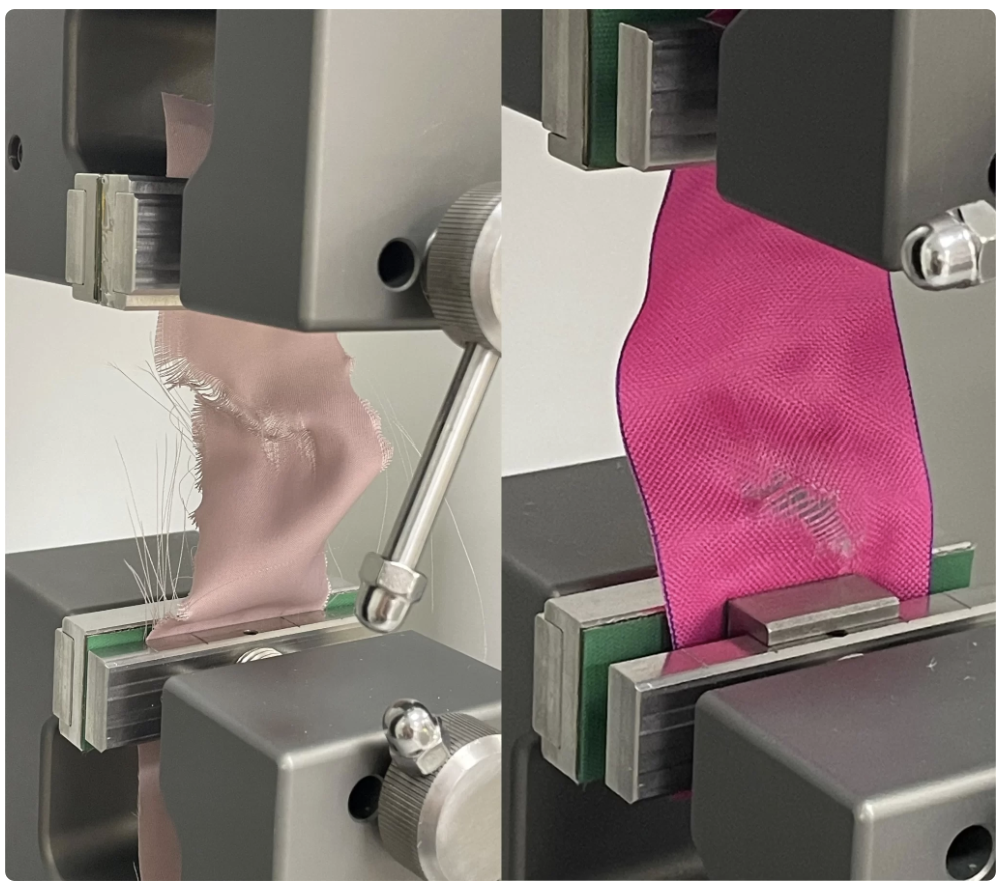

Jungle Test

- Purpose: The jungle test is designed to simulate extreme environmental conditions, such as high humidity, high temperature, and exposure to mold and mildew. It is used to evaluate how well materials withstand harsh conditions that could lead to degradation over time.

- Procedure: Samples are exposed to controlled environments with high humidity (often above 90%) and elevated temperatures (typically around 37°C or higher) for a set period, usually ranging from a few days to several weeks. This test helps to assess the material’s resistance to conditions that might be found in tropical or subtropical climates.

- Application: Commonly used for testing the durability of outdoor gear, military equipment, and footwear, particularly in humid or tropical environments.

Hydrolysis Test

- Purpose: The hydrolysis test is used to assess the degradation of materials, particularly polymers like polyurethane, when exposed to moisture over time. Hydrolysis can cause the breakdown of chemical bonds in materials, leading to loss of mechanical properties, such as strength and flexibility.

- Procedure: In this test, samples are exposed to moisture (often in a humid environment or submerged in water) at elevated temperatures for a prolonged period. The conditions mimic the effects of long-term exposure to moisture and heat, which can lead to material degradation.

- Application: Frequently used in testing synthetic materials like foams, coatings, and adhesives. In footwear, for example, hydrolysis can lead to the breakdown of the midsole or outsole, causing the shoe to lose its structure and integrity.

Tests are conducted in Temperature and Humidity Chamber (Environment Chamber) to simulate environment conditions that materials or products endure.