How To Improve Textile Testing Technology?

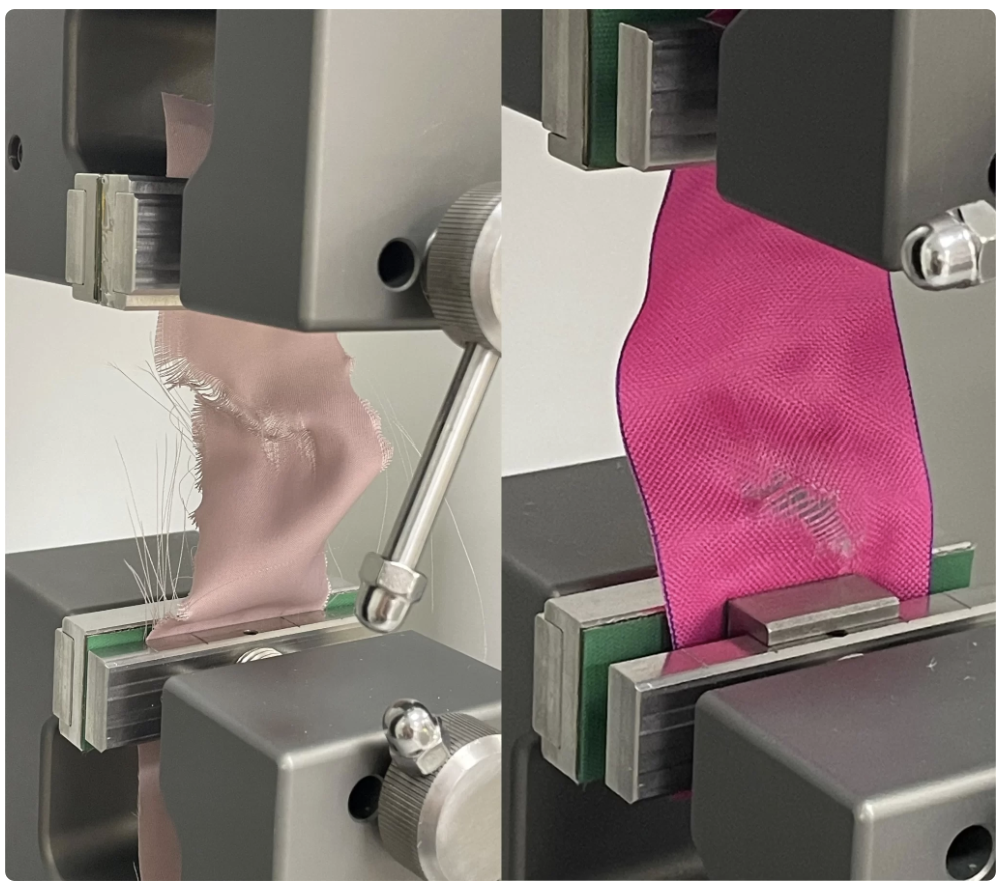

Improving textile testing technology includes better methods and innovation. These ensure higher efficiency, accuracy, and reliability in testing textile properties. This can include the use of automated testing tools. They lessen human error and improve precision.

Using advanced software for data analysis offers deeper insights into test results. It helps manufacturers understand textiles’ performance better. Of course, modern technology like AI and 3D can improve testing. They give a more detailed and correct assessment of materials.

Also, we can develop sustainability tests. They measure textiles’ impact on the environment. They support eco-friendly manufacturing.

What Is Quality Control In Textile Testing?

Quality control in textile testing is a planned process. It ensures that textile products meet the standard and customer expectations. It includes a series of tests and inspections. They happen at many levels of production and find defects. They assess the quality of raw material, semi-finished items, and finished products.

Of course, these tests often evaluate many factors. These include strength, durability, color quality, shrinkage, and chemical makeup. By doing this, manufacturers can keep high standards. And they will also cut waste and please customers. This will improve their brand reputation. Finally, quality control in textile testing is key. It is needed to offer reliable, high-quality textile products. These products must meet rules and customer needs.

Why Is Quality Control Important In Textile Testing?

We need quality control in textile testing. It is needed for many reasons. It helps to ensure the success and reliability of textile products. And it ensures the textile meets industry standards. It also covers regulatory needs and consumer expectations. Here are some of the key reasons why quality control is important in textile testing:

-

Guarantees Product Steadiness

It aids in maintaining consistency in textile products. By testing often, the manufacturer can ensure each batch of textiles meets the quality standard. This consistency is crucial. It helps build brand trust and ensure customer satisfaction.

-

Compliance with Values and Rules

Textile products should obey with different industry standard and regulations. These include related to safety, performance and environmental impact. Its processes ensure that textiles meet these standards. They help manufacturers avoid legal issues and recalls. It also facilitates entry into global markets with stringent rules may apply.

-

Reduces Defects and Waste

Through rigorous QC testing, we can identify defects in raw materials or finished products early. This finding allows for corrective actions. They will reduce defect and waste. The lower defect rates can also make cost savings for producers.

-

Enhances Customer Satisfaction

Of course, top-notch textile products lead to better customer satisfaction. Quality checking makes sure products meet consumer expectations. They must do so in areas like durability, appearance, and performance. Happy customers become repeat buyers. They recommend the products to others. This builds brand loyalty and fame.

-

Improves Efficiency and Productivity

Considering quality control in textile testing can develop the production process. By fixing the quality issues often, the manufacturer can boost their efficiency. They can do this by finding and fixing the issues a lot. The process is reliable. It leads to faster turnaround times. It can effectively meet market demands.

-

Supports Brand Reputation and Competitive Advantage

Steadily quality products will easily enhance the brand’s reputation. In the tough market, a strong reputation for quality can be crucial. It matters because it attracts more customers and allows for higher prices. The QC plays a crucial role in managing and improving the brand’s market position.

-

Facilitates Innovation and Improvement

QC offers valuable data that can be used for constant development and innovation. By analyzing the QC data, the producer can easily spot the trend. They can then make new technologies. They can understand the root of defects in materials. This will help improve product quality.

Testing in textiles needs quality control. It is crucial for ensuring product consistency and deals with many factors. It will boost efficiency and support brand reputation. Thus, it is key for successful textile manufacturing.