5 Common Mistakes When Investing in Textile Lab Equipment (and Practical Solutions)

5 Common Mistakes When Investing in Textile Lab Equipment (and Practical Solutions)

Investing in textile lab equipment is not simply about purchasing a few machines for your lab—it is a strategic decision that has long-term implications for your quality control capability, product certification process, and overall credibility within the supply chain.

At Amitec, we’ve supported numerous factories, brands, and partners through the process of upgrading their testing capabilities. Here are the 5 most common mistakes companies make—and practical advice to help you make smarter, more sustainable investments.

1. Investing Without a Clear Testing Objectives

One of the biggest mistakes is making impulsive decisions—buying equipment based on trends, referrals, or simply because “others are using it too.” The result? The equipment may not fit your actual testing needs, may not meet brand standards, or may be underutilized.

Solution:

Start by clearly identifying your testing goals, output standards, operation scale, and brand/customer requirements. These factors are essential for choosing the right equipment and ensuring a strategic investment.

2. Lack of Understanding of Machine Specifications and Test Methods

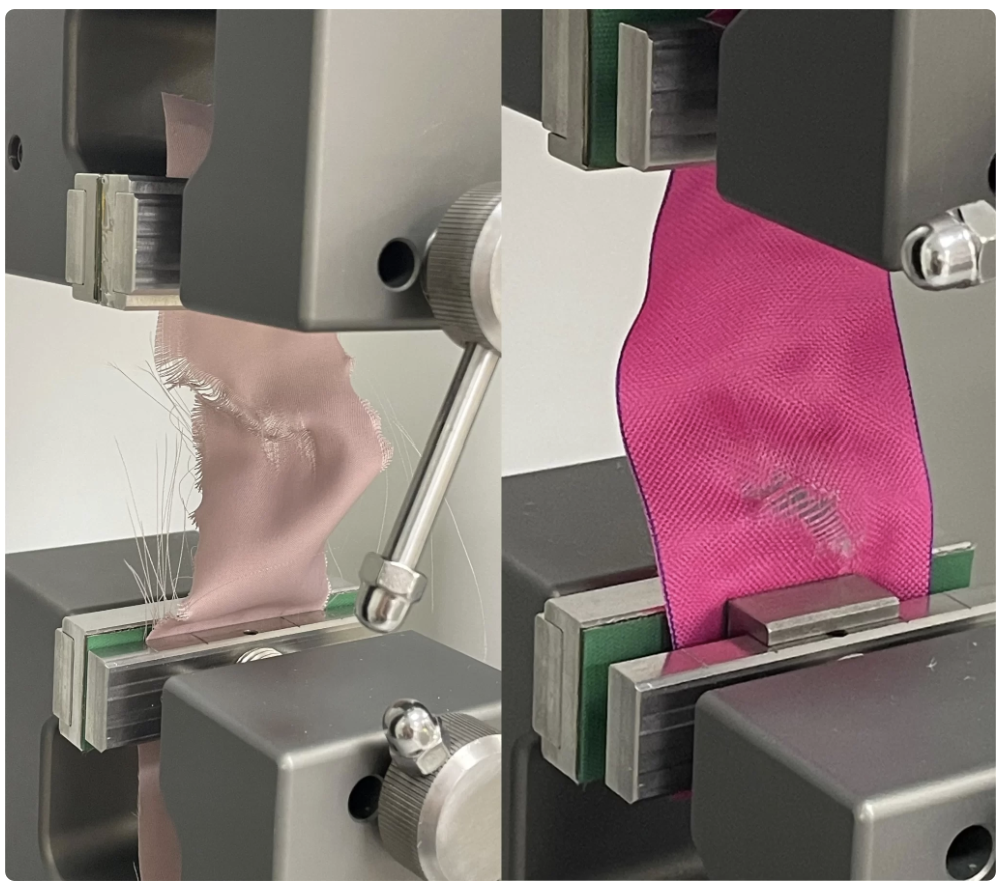

Many factories purchase textile lab equipment based solely on the product name, not realizing that test methods and technical requirements can vary greatly—especially across brands like Adidas, Nike, Decathlon, or Puma. Two machines might both test colorfastness or tensile strength but operate under entirely different standards.

Solution:

Work with consultants and suppliers who possess deep industry knowledge. Choose providers who can explain the differences between machines, test methods, and brand-specific standards—offering clear options for comparison and selection.

3. Prioritizing Low Price Over Long-Term Value

Choosing equipment based solely on low upfront costs can lead to high maintenance expenses, low accuracy, or extended downtime—especially for machines that require high repeatability and reliable QC data.

Solution:

Evaluate the Total Cost of Ownership (TCO): initial investment, operating costs, maintenance, calibration, and long-term usability. A higher-cost machine with greater stability and long-term support often proves to be a better investment.

4. Overlooking Maintenance, Calibration & After-Sales Support

Many businesses fail to consider the availability of local maintenance, routine calibration, or after-sales service. When issues arise or software updates are needed, the lack of timely technical support can disrupt operations.

Solution:

Choose a supplier with a certified local support team in Vietnam—trained by global manufacturers and capable of offering preventive maintenance and scheduled calibration services.

TAV Group – Amitec, as the official representative of top global brands, ensures reliable, ongoing support.

5. Ignoring Lab System Integration and Future Expansion

Investing in individual textile lab equipment without considering system compatibility, workflow integration, and staff capacity often leads to inefficiency. Many factories also lack a long-term roadmap for adopting innovations like IoT or automation.

Solution:

Develop a comprehensive lab plan—from layout design and machine selection to data management systems. Consider investing in IoT-ready Smart Lab solutions or digital textile lab solution to future-proof your lab and scale seamlessly when needed.

Get It ‘Right First Time’ – Best Matching Solutions – Long-Term Partnership

Choosing a competent and trustworthy partner is crucial to the success of your investment. As the exclusive distributor of brands like ChiuVention, Electrolux Professional, Verivide, and Miele Professional in Vietnam, Amitec offers more than just textile lab equipment—we accompany you through every step:

-

Defining your testing objectives

-

Proposing the most suitable textile lab equipment

-

Comparing test methods and machine types

-

Deployment – Training – Scheduled Maintenance & Calibration

-

Roadmap consulting for medium- and long-term lab development like digital textile lab solution